TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® 1λ UV Fused Silica Windows are precision manufactured using UV-grade synthetic fused silica. In addition to superior transmission, the synthetic fused silica of these optical windows exhibits higher thermal properties, exceptional purity, and excellent environmental durability for demanding applications. The windows are ideal for cost-sensitive broadband applications and are available uncoated or with broadband anti-reflection coatings. TECHSPEC® 1λ UV Fused Silica Windows have circular and square sizes ranging from 5mm to 100mm. λ/4 or λ/10 UV Fused Silica Windows are also available.

Note: New additions to this product family may be specified with a transmitted wavefront distortion (TWD) specification instead of a surface flatness. For more information on the difference between these two specifications, see our application note on Understanding Optical Windows.

| FUSED SILICA | |

|

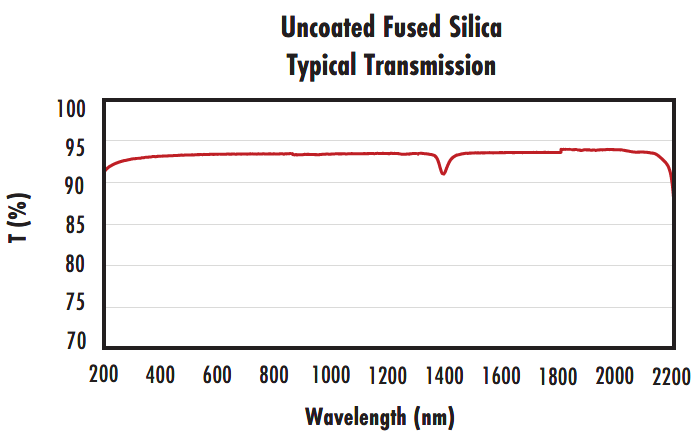

Typical transmission of a 3mm thick, uncoated fused silica window across the UV - NIR spectra. |

|

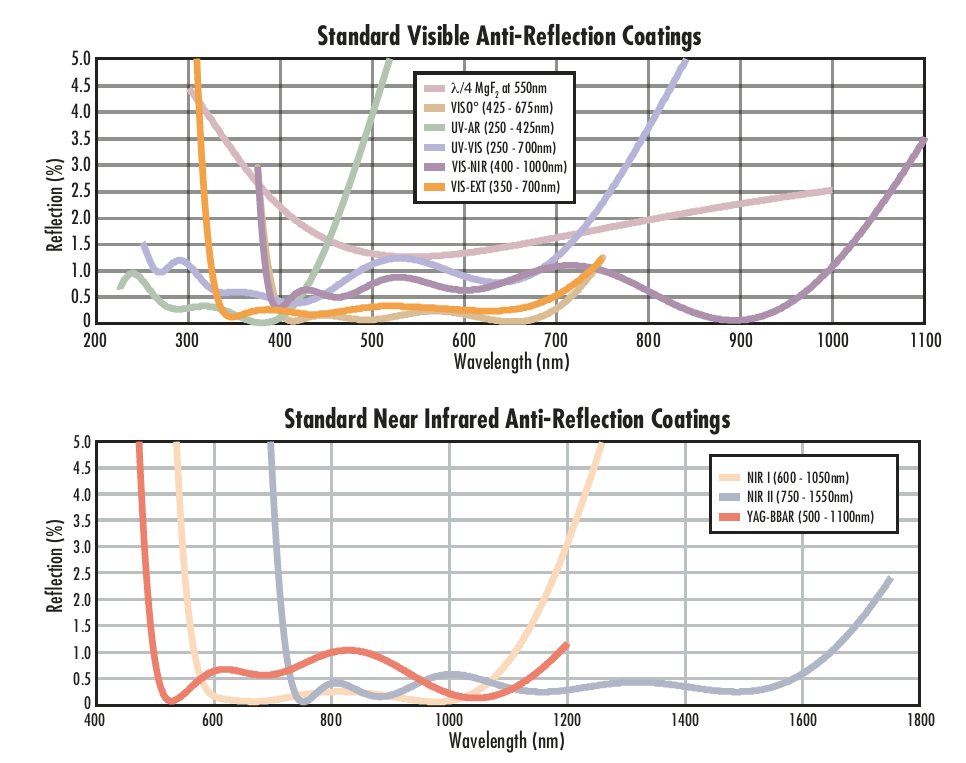

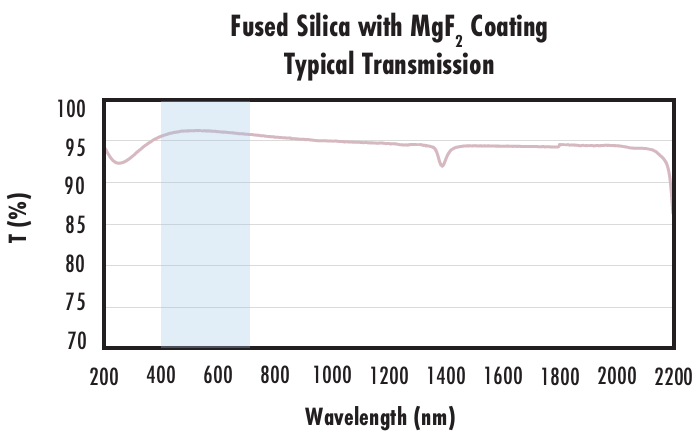

Typical transmission of a 3mm thick fused silica window with MgF2 (400-700nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 1.75% @ 400 - 700nm (N-BK7) Data outside this range is not guaranteed and is for reference only. |

|

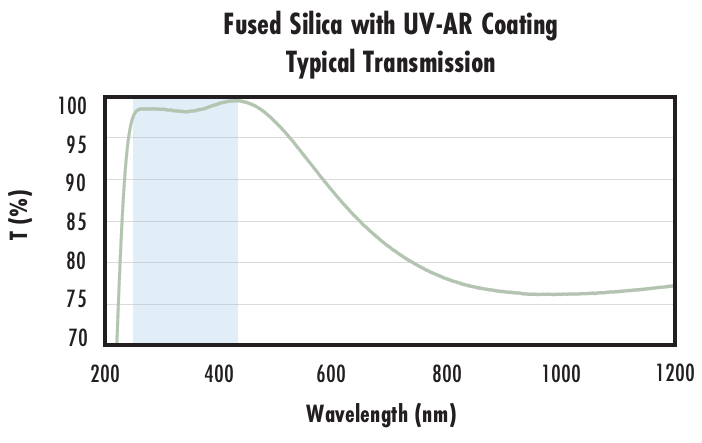

Typical transmission of a 3mm thick fused silica window with UV-AR (250-425nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 1.0% @ 250 - 425nm Data outside this range is not guaranteed and is for reference only. |

|

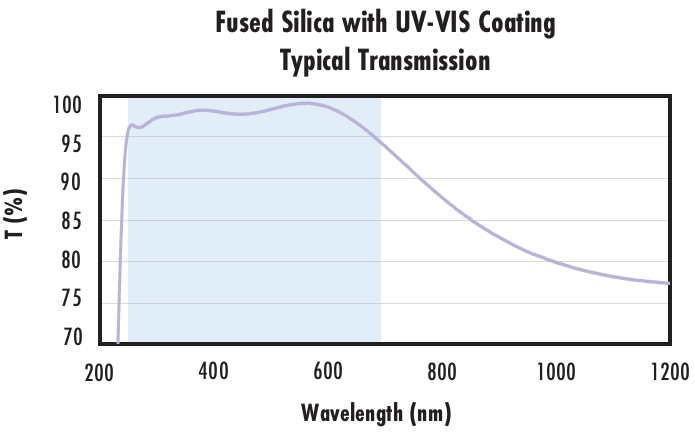

Typical transmission of a 3mm thick fused silica window with UV-VIS (250-700nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 1.0% @ 350 - 450nm Data outside this range is not guaranteed and is for reference only. |

|

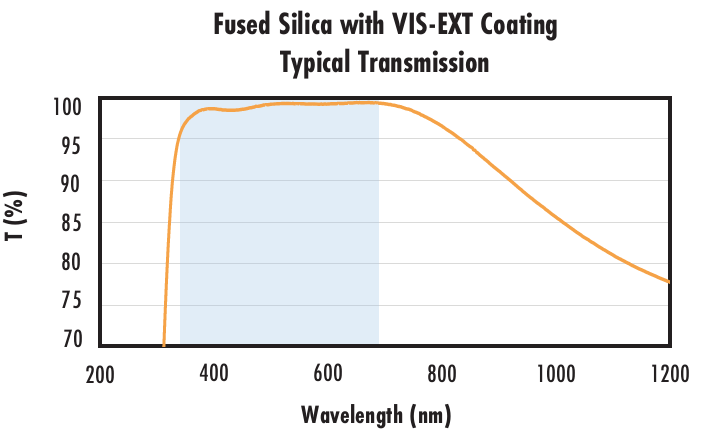

Typical transmission of a 3mm thick fused silica window with VIS-EXT (350-700nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 0.5% @ 350 - 700nm Data outside this range is not guaranteed and is for reference only. |

|

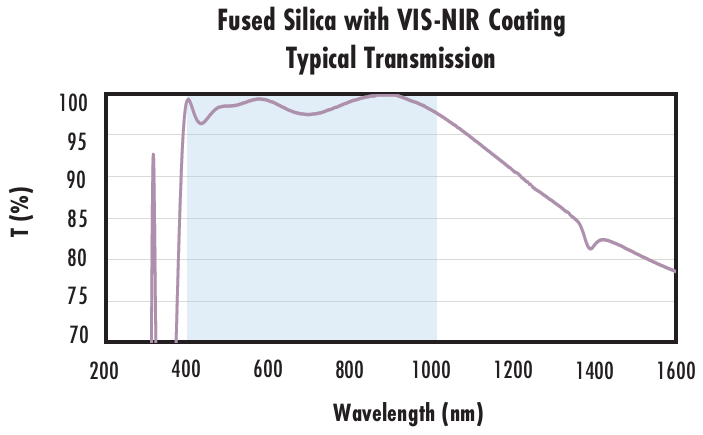

Typical transmission of a 3mm thick fused silica window with VIS-NIR (400-1000nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 0.25% @ 880nm Data outside this range is not guaranteed and is for reference only. |

|

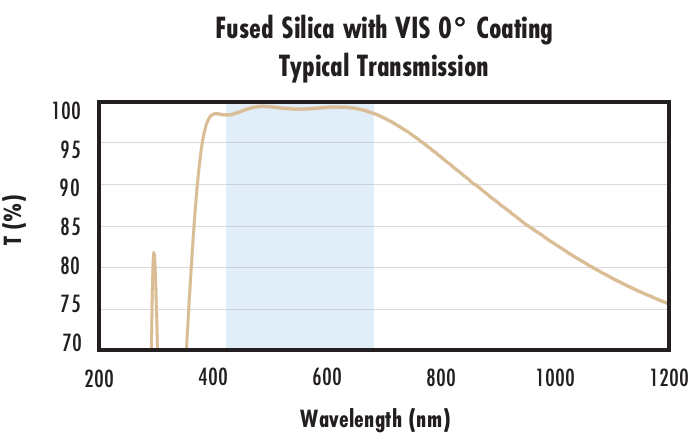

Typical transmission of a 3mm thick fused silica window with VIS 0° (425-675nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 0.4% @ 425 - 675nm Data outside this range is not guaranteed and is for reference only. |

|

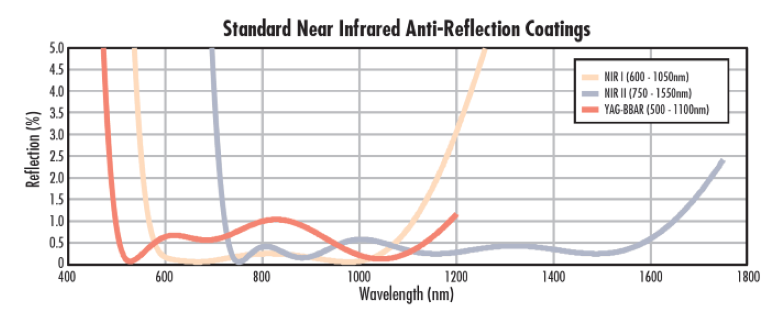

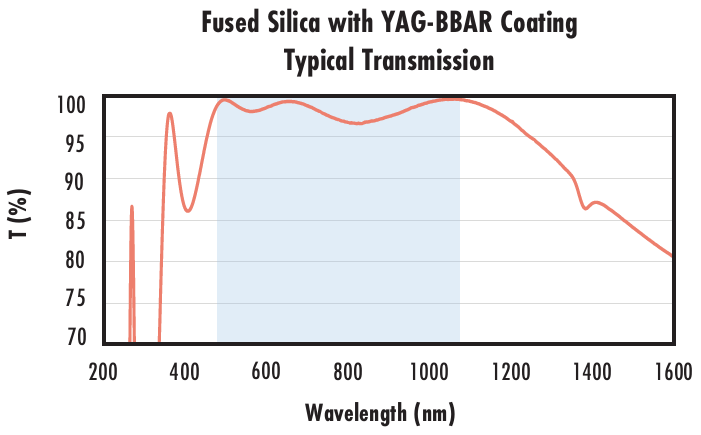

Typical transmission of a 3mm thick fused silica window with YAG-BBAR (500-1100nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 0.25% @ 532nm Data outside this range is not guaranteed and is for reference only. |

|

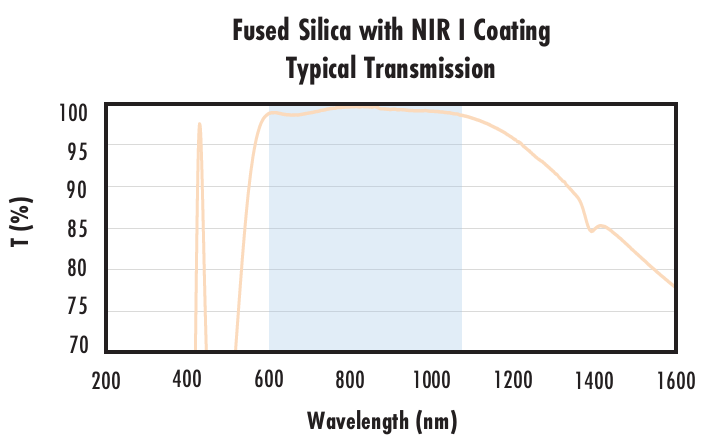

Typical transmission of a 3mm thick fused silica window with NIR I (600 - 1050nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 0.5% @ 600 - 1050nm Data outside this range is not guaranteed and is for reference only. |

|

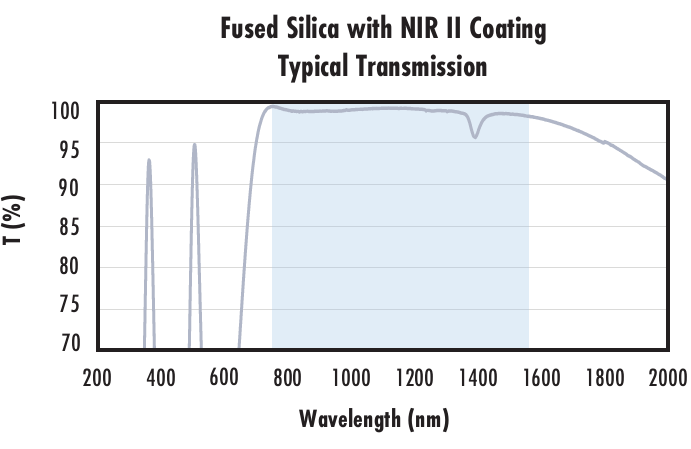

Typical transmission of a 3mm thick fused silica window with NIR II (750 - 1550nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 1.5% @ 750 - 800nm Data outside this range is not guaranteed and is for reference only. |

1-800-363-1992

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2025, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act