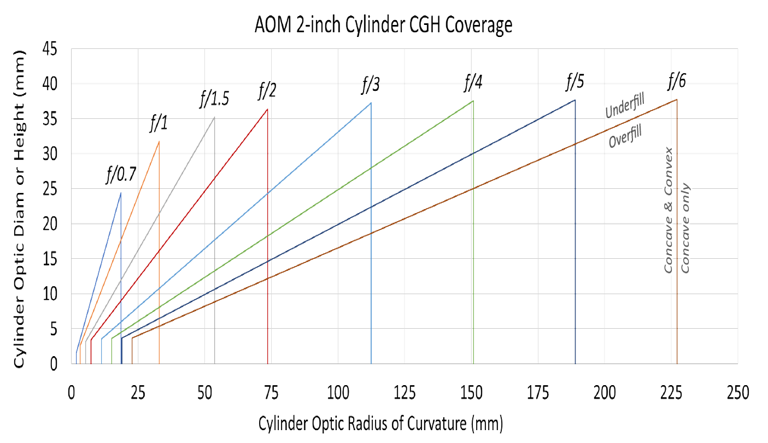

Arizona Optical Metrology (AOM) Cylinder Computer Generated Holograms (CGH) extend the capabilities of an interferometer to inspect cylindrical optics for fast, full aperture, and high resolution surface figure error metrology. A complete line of cylinder CGH f/#s is available, allowing for a range of convex and concave cylindrical optic surfaces to be tested, and reducing the number of test plates or interferometric reference surfaces required in a metrology lab. AOM 2-inch cylinder CGHs are mounted in mechanical frames that kinematically mount to a required 6 degree-of-freedom stage for precision alignment of the CGH to the interferometer. Arizona Optical Metrology (AOM) Cylinder Computer Generated Holograms (CGH) are optimized for use with industry standard 4” aperture, 632.8nm HeNe laser wavelength interferometers with a reference transmission flat. Each Cylindrical Null CGH is provided with a Certificate of Quality, indicating the tested performance specifications.

Note: These CGHs require the use of either the 6 degree-of-freedom Fine Positioning Stage (#25-684) or 6 degree-of-freedom Fine Positioning Stage with Z-Axis (#25-685). The CGH cell magnetically connects to the stage kinematically for fast and repeatable positioning.

AOM cylinder computer-generated holograms (CGH) enable interferometric measurement of cylindrical optics. The surface figure error of convex and concave cylindrical optics can be measured over the full aperture using a CGH. The cylindrical radius of curvature can also be measured with a radius-enabled interferometer bench.

AOM standard cylinder CGHs include a Fused Silica substrate with cylindrical null pattern, retro alignment pattern, anti-reflection coated back surface, and a mechanical cell with 1/4” stainless steel mounting balls to interface to an AOM FP3 alignment stage.

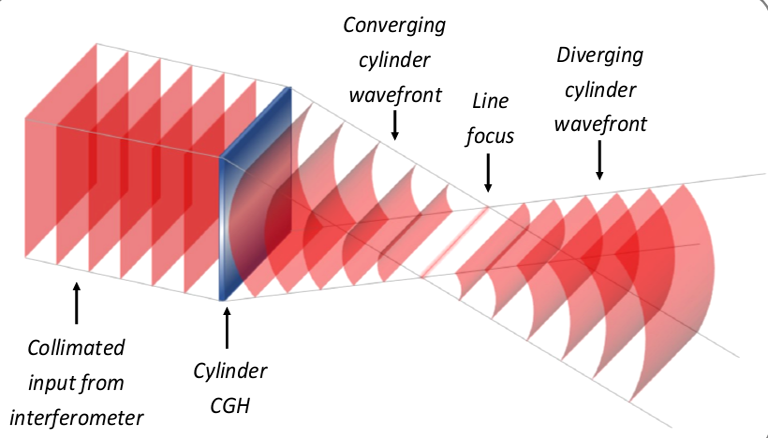

A cylinder CGH is a diffractive optical element which converts a collimated interferometer wavefront into a converging cylindrical wavefront. Concave and convex cylinder optics can be measured in a confocal null test with the same CGH. Convex cylinder optics should be positioned in the converging wavefront, and concave cylinder optics in the diverging wavefront.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®