TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

| Volume Pricing | |

|---|---|

| Qty 1-5 | A$488.00 each |

| Qty 6-24 | A$414.40 each |

| Qty 25-49 | A$366.40 each |

| Need More? | Request Quote |

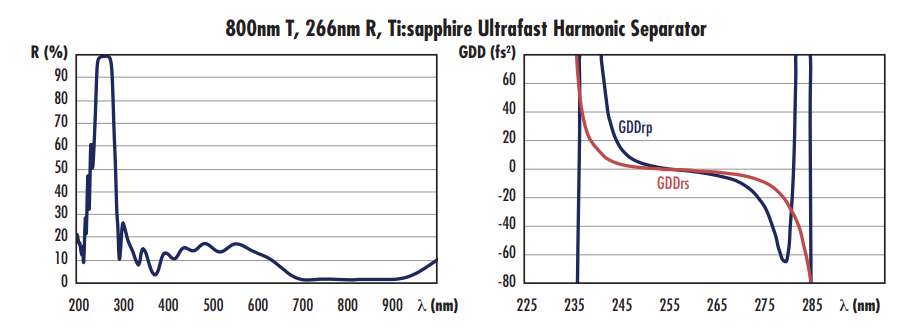

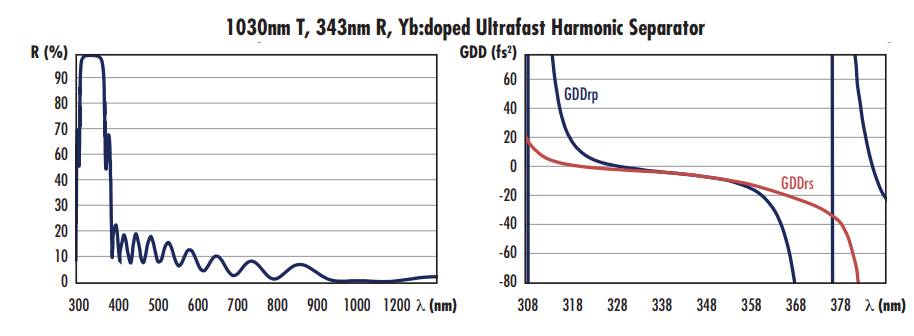

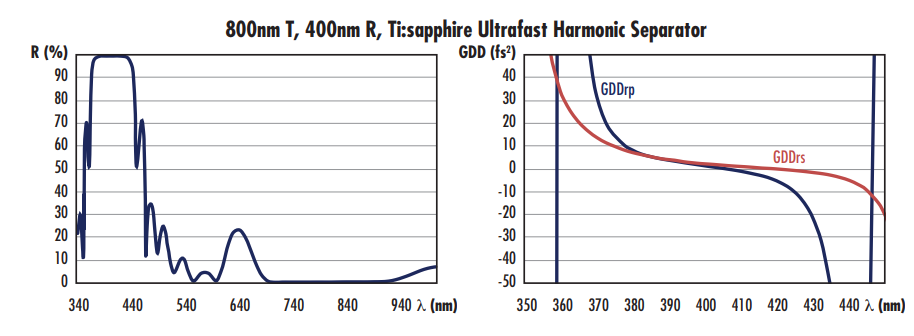

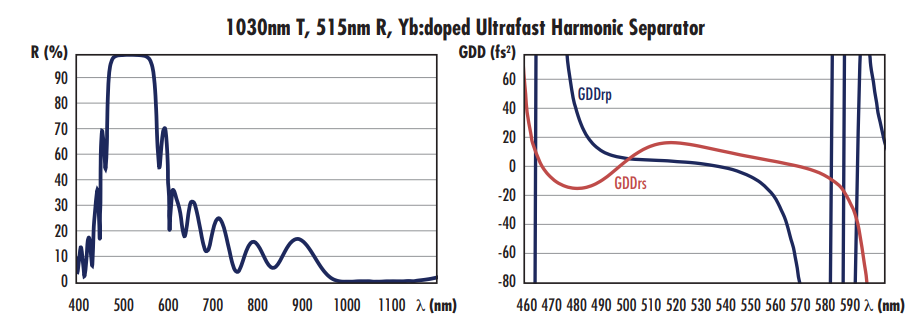

TECHSPEC® Ultrafast Harmonic Separators, also known as Ultrafast Harmonic Beamsplitters, are used to reflect the second or third harmonic of femtosecond lasers while transmitting the fundamental pulse. The reflective surface is designed to have high reflectivity and a low Group Delay Dispersion (GDD) of ±20fs2 to minimize pulse dispersion. The back surface is coated with an anti-reflection coating to enhance the transmission of the fundamental light. TECHSPEC Ultrafast Harmonic Separators provide low wavefront distortion and feature high quality, thin UV fused silica substrates with 10-5 surface quality. Designs for separating the harmonics of 800nm and 1030nm (Ti:sapphire and Yb:doped fiber) lasers are available.

Please contact us if your application requires an Ultrafast Harmonic Separator designed for custom wavelengths.

Edmund Optics offers comprehensive custom manufacturing services for optical and imaging components tailored to your specific application requirements. Whether in the prototyping phase or preparing for full-scale production, we provide flexible solutions to meet your needs. Our experienced engineers are here to assist—from concept to completion.

Our capabilities include:

Learn more about our custom manufacturing capabilities or submit an inquiry here.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®